The term "AQL 2.5" forms part of hundreds of purchase orders sent to Chinese manufacturers however what does AQL 2.5 mean? Buyers and suppliers understand and agree that it is some kind of tool to measure the quality during a pre-shipment inspection. While this is true, buyers, suppliers and third party inspection companies may interpret it differently therefore more precise information are required to avoid misunderstandings.

The term "AQL 2.5" forms part of hundreds of purchase orders sent to Chinese manufacturers however what does AQL 2.5 mean? Buyers and suppliers understand and agree that it is some kind of tool to measure the quality during a pre-shipment inspection. While this is true, buyers, suppliers and third party inspection companies may interpret it differently therefore more precise information are required to avoid misunderstandings.

What does AQL 2.5 mean?

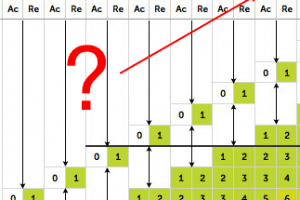

In the strict sense of the term, "AQL 2.5" is a partial application of the ISO 2859-1 standard, which is also copied in other normative bodies such as ANSI: "The acceptable quality limit (AQL) is the worst tolerable process average (mean) in percentage or ratio that is still considered acceptable; that is, it is at an acceptable quality level".

AQL 2.5 means the buyer considers as acceptable quality limit a defect rate of 2.5% of the total order quantity.

Defects classification and acceptable quality limit

In the quality control industry, defects are classified per critical, major and minor. If the buyer only mentions AQL 2.5, it means that the buyer accepts all kind of defects: critical, major or minor, to be present in the manufactured goods at a level of 2.5% of the total order quantity. Knowing that a critical defect is dangerous for the user, it is quite risky for the buyer to include in the 2.5% such defect type.

It is highly recommended to define an acceptable quality limit for each defect type: critical, major, minor.

Other interpretations are possible such as: considering that the AQL standard applied in the quality control industry is AQL 0 for critical defects, AQL 2.5 for major defects and AQL 4.0 for minor defects. However without those details, the supplier and the Quality Control company may consider the client only require a limit on major defects and no limits on minor defects or critical defects.

Need of precise instructions about the Acceptable Quality Limits

Just stating "AQL 2.5" without any further information is definitely not enough. Buyers should clearly define its acceptable quality limits per defect types in order to avoid any misunderstanding.

In addition, it is also necessary to define the AQL sample size, the defect category definitions (if different from the standard one used by third party inspection companies), the tolerances if required, etc.

And you: how do you mention your acceptable quality limits to your supplier and quality control partner?