After performing the quality inspection in the factory, the inspector prepares the draft report on-site and reviews with the factory manager. However a draft report is different from the final report and the buyer should be fully aware of the differences to avoid any misunderstanding of the quality inspection result.

After performing the quality inspection in the factory, the inspector prepares the draft report on-site and reviews with the factory manager. However a draft report is different from the final report and the buyer should be fully aware of the differences to avoid any misunderstanding of the quality inspection result.

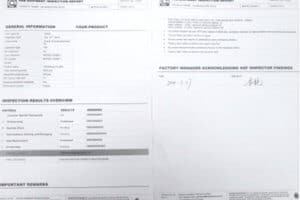

Draft quality inspection report

The draft quality inspection report is a first overview of the goods quality:

- It is made to show the manufacturer the main findings while the QC is still in the factory

- The first page lists all the defects found, as well as all the non-conformities compared to the approval sample or buyer's product specifications

The inspector is obliged to present the draft quality inspection report to the manufacturer in order for them to acknowledge any quality issues found during the inspection (the manufacturer should sign the draft document to confirm he is aware of the inspection findings).

Note: In this case neither the draft report document nor any other paperwork regarding the inspection's findings are left at the factory. Unless the buyer has requested it prior to the inspection date.

Final quality inspection report

The final quality inspection report is very detailed:

- Every single defect, non-conformity and conformities are mentioned and explained

- All the tests performed are listed

- Pictures of each findings are shown in order to ensure a clear understanding of the situation from the buyer

The final report should be checked in detail by the inspection supervisor before being sent to the buyer. The objective is to ensure all the specifications have been verified, all the tests have been performed and the explanations are clear. That's the reason why discrepancies can be found between the draft and the final quality inspection report, and the reason why the draft report copy should not be given to the factory.

The final quality inspection report is the only one that should be taken into account by the buyer to decide if the goods quality is acceptable or if he should put some corrective actions in place with the manufacturer. The draft report is only a first overview, it needs to be digested and checked.

And you: which other differences do you find between the draft and final quality inspection report?