When doing inspections, one of the most common tests done by inspection firms is the Carton Drop test. By testing how durable the box is, you can see how the cartons themselves will hold up during shipment and what potential damage could be done to the products inside. The test is based off of the ISTA (International Safe Transit Association) standard.

But how exactly are these carton drop tests done?

- The products must be checked for defects before testing to ensure normal functionality and packaging. The client ideally should define product and packaging damage criteria beforehand.

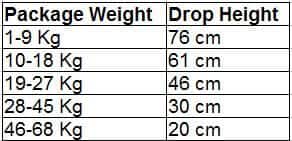

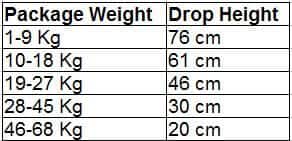

- Using the chart below, determine what height your products should be dropped from:

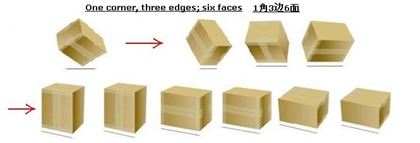

- Next, you may conduct the test by dropping the boxes on the corners, edges and faces indicated below. There are 10 different drops

.

.

Once you have done your drop tests, how do you make a conclusion from the results? Normally, there are three different types of outcomes: Pass/Fail/Pending.

- Pass: No damage or breakage to packaging. No functionality or safety issues found with the product.

- Fail: Product is damaged or broken or safety issues, such as sharp edges or small loose parts, are revealed after testing.

- Pending: Packaging including outer carton, inner boxes or unit packaging are damaged, but the product remains in tact.

Unfortunately, many factories are hesitant to allow this testing as the risk of damage to products (which they would have to replace) is present. However, having your factory agree to compulsory drop testing will help to ensure that your products are packaged in a safe way and will not be damaged during shipment.