Inspecting garments is tricky business. You must be sure to measure sizes, check material weight and composition, and of course check for cosmetic defects. Cosmetic defects on clothing are numerous: from missing buttons, to split seams to holes. But checking fabric rolls should be easy then, right? There are not as many possible defects and measurements are easier, right? Actually, this is incorrect; Making QC on fabric rolls is very challenging and requires precise methods. The inspector must check conformity; for example are the rolls the right fabric, colors and feel, the right length and packed properly?

Inspecting garments is tricky business. You must be sure to measure sizes, check material weight and composition, and of course check for cosmetic defects. Cosmetic defects on clothing are numerous: from missing buttons, to split seams to holes. But checking fabric rolls should be easy then, right? There are not as many possible defects and measurements are easier, right? Actually, this is incorrect; Making QC on fabric rolls is very challenging and requires precise methods. The inspector must check conformity; for example are the rolls the right fabric, colors and feel, the right length and packed properly?

Method for QC on Fabric

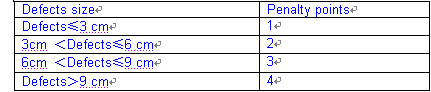

Beyond these simpler checks, two industry methods used are the Ten point and Four point systems. The most commonly used is the Four point system. Within this system, fabric rolls are graded for defects. Each defect receives a certain number of points, and after inspection, of course you hope for the lowest number of points possible. The point system is as follows:

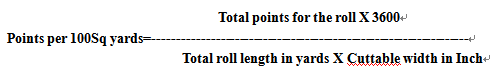

As you can see, the more severe the defect, the more points that will be taken off. It is up to the client to set the maximum number of defects per 100 yards, which is a maximum of 30 points per 100. The inspector will add up the defects points and then use the following formula to determine the rate of points per 100 yards.

After finding the stats for the individual rolls, the client is given:

- Average points of all rolls sampled

- Proportion of rolls above limit

Generally, an inspection company can check 1000 yards at most during one day, so if an average roll is 50 yards, that would mean 20 rolls inspected, which is what the proportion would be out of. Inspecting fabric is quite time-intensive and requires significant expertise. In discussing with your QC agents your textile requirements, you can choose the best acceptable limit of points to ensure that you will receive a shipment of good quality.