Interpreting the percentage of defects from the AQL result

When reading the AQL result of an inspection report, it is quite natural to calculate the % of defects over the sample size and then estimate the number of defective goods on the whole lot. However, this approach is flawed. Why is interpreting the percentage of defects from the AQL result a mistake? How is the AQL result to be read then?

Why are the percentage of defects from the AQL result different?

While inspecting the total order quantity, it is highly likely one will find a different number of defects compared to the AQL result, lower or higher. If not, it is merely a lucky day. For example: on a 100 pcs order, if we take a sample size of 10 pcs and 3 of those items are defective, it does not mean that there will be in total of 30 defective pieces on the total order. The AQL does want to get close to this result; however, the only way to know the total defective quantity is to check the total order quantity.

The AQL standard takes into account the probability of having this defect on the overall lot only. Its purpose is to provide information about the defects available compared to the acceptance quality limits of reference.

How to read the AQL table result?

Each defect and its classification (minor, major, critical) should be analyzed seperatly and carefully, paying close attention to each though the number of the defect is low. This is because there is always the probability that the number of defects on the overall order could be higher or lower than the AQL result.

Therefore, one should ask oneself: am I willing to accept such defect(s) if present in a higher quantity on the total order? If the answer is no, then the supplier should be requested to improve the quality of the goods.

Also, in some inspection companies, a defect can be reported separately from the AQL table when it appears on too many samples (>10%-20 % of the sample size in general). This allow more clear reporting of the situation. We usually call it a “general defect”, it can be a minor or major defect. In any case, it should be looked at closely as it is likely to be present in a high percentage on the whole lot.

The AQL standard is a very useful tool to identify the major defects in production, however it remains a probability. To ensure the most representative AQL result, it is highly recommended one use the highest standards of the AQL whic is, level II or III only.

And you: how are you used to interpreting the AQL table result?

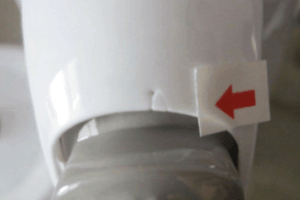

Photo taken during a water boiler pre-shipment inspection

Where do manufacturers send their defects in China?

@Anthony: Thank you for your question. Defective products can be improved in most cases. For the ones that should be thrown away, you should clearly mention your conditions to the manufacturer in advance. We may recommend to include it in the purchase order and in a contract written in Chinese for sensitive products.