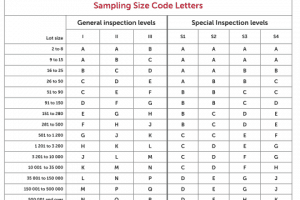

From the previous article about the AQL, you should now understand for the most part how to use an "AQL table" when getting an inspection. But what are the Inspection Levels “I”, “II” and “III” and how do you know which to use?

From the previous article about the AQL, you should now understand for the most part how to use an "AQL table" when getting an inspection. But what are the Inspection Levels “I”, “II” and “III” and how do you know which to use?

The standard level used is Level II. Simply put, Level I entails checking less samples, while Level III involves tightening up and checking more samples.

While Level II is an acceptable level for most importers in most situations, there certainly are circumstances in which selecting Levels I or III are helpful.

For example, if you have been working with a factory for years and if you continually receive high quality from them, checking less samples and switching to Level I might be sensible. It would lessen the number of days of inspection necessary, which means lower inspection costs. But it would be pretty risky if you are not already confident in their product quality.

Conversely, if you are working with a factory that you do not trust as much and have had past quality issues with, checking more samples with a Level III would be prudent (for more info, you can read 3 General Inspection Levels For QC Sampling With AQL).

If you are unsure of what Inspection level to use, you can work with your QC partner to determine the most appropriate level given your particular circumstances.