The GSM test is a measurement of Grams per Square Meter, and is one of the most important methods of determining the weights of knitting fabric, non-woven fabric or paper cardboard. Woven fabric, fabric with coating, or laminated fabrics are not as commonly tested using the GSM method, therefore the customer would need to give unique specification prior to GSM testing.

The GSM test is a measurement of Grams per Square Meter, and is one of the most important methods of determining the weights of knitting fabric, non-woven fabric or paper cardboard. Woven fabric, fabric with coating, or laminated fabrics are not as commonly tested using the GSM method, therefore the customer would need to give unique specification prior to GSM testing.

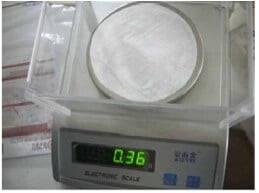

GSM provides the weight per unit area or the weight per unit length or “weight per running yard” in lament terms. Before performing a standard GSM test, you must acquire fabric samples using a GSM Cutter. The GSM Round Cutter is a tool used in extracting precision-cut samples of 100 square centimeters. The GSM cutter is a sleek, rounded metal device with a knob fitted in the center. At the bottom, the blades of the cutter cleanly cut dishes of fabric to be placed on the testing scale. Normally, 10 fabric disks are cut as samples for weighing. The electronic balance is used to determine weights of each sample, and the total is averaged for the official GSM number.

The totaled average will help manufacturers and inspectors find flaws and stick to standards. It is important to note, however, that other factors can hamper the accuracy of a GSM test. The moisture and atmospheric humidity can temporarily affect the GSM of cotton fabric samples by adding water weight. Therefore, it is important to test fabric samples under controlled atmospheric conditions. Above all else, be sure to double-check the reliability of your scale before testing. A couple of weeks ago a major lab performed a GSM test with an unbalanced scale. By the time the lab learned of its calibration flaw, the factory had been forced to reproduce the samples. Normally however, the testers allow for a 5% flexibility within the range of a client’s requirements for tolerance of human error.