While an importer's specs and list of expected product defects are vital to perform an adequate inspection, reputable inspection firms like AQF have internal inspection checklists for any range of products.

While an importer's specs and list of expected product defects are vital to perform an adequate inspection, reputable inspection firms like AQF have internal inspection checklists for any range of products.

The benefit of these detailed inspection checklists is that the inspection firm already understands the expected defects and knows what to check, even before receiving the client's feedback. After receiving the client's information, the inspection firm can further tailor the service to the specific needs of the client.

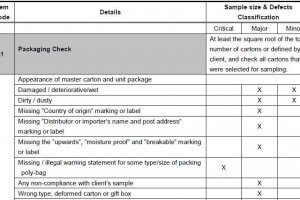

You can see in the below sample checklist a breakdown of potential defects and possible tests. The right columns specify whether a defect classifies as a Critical, Major, or Minor defect.

Ceramic Goods Inspection Checklist

Any questions? Conact an expert now!